- Gratis verzending vanaf € 100,-

- Veilig bestellen en betalen

- 14 dagen bedenktijd

- Klanten geven ons een 9.6/10

Heeft u een vraag over dit product?

Stel ons uw vraag

Productomschrijving

Forge intercooler Renault Megane Mk4 > RS 280 Cup (17-)- Hand fabricated

- Lightweight - Tube and Fin core

- Stepped core design

- 41% capacity increase over OE intercooler

- Gains of 8bhp (see description for more information)

- Gains of up to 20NM (see description for more information)

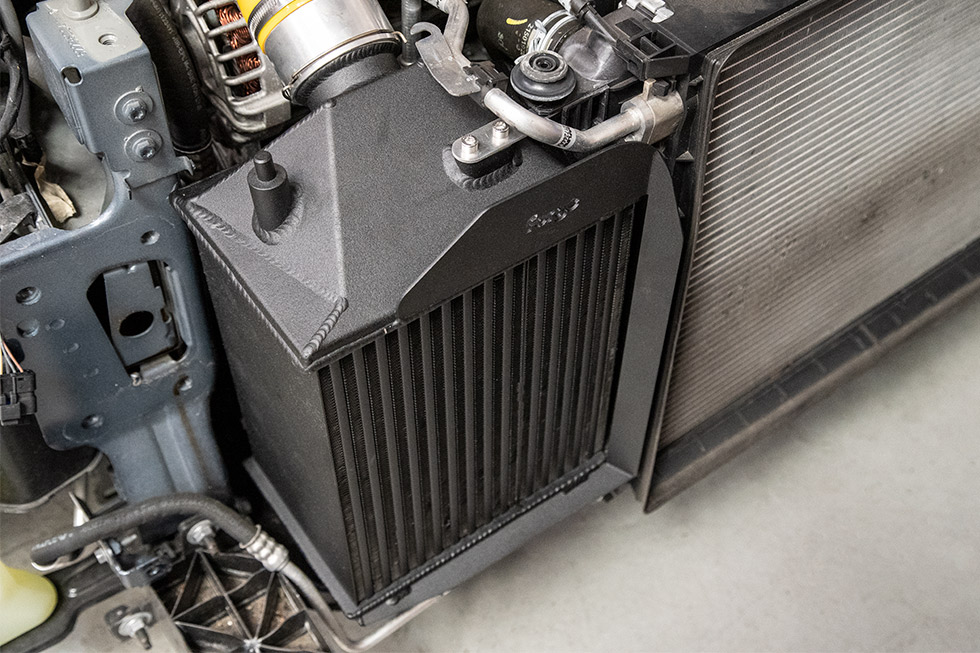

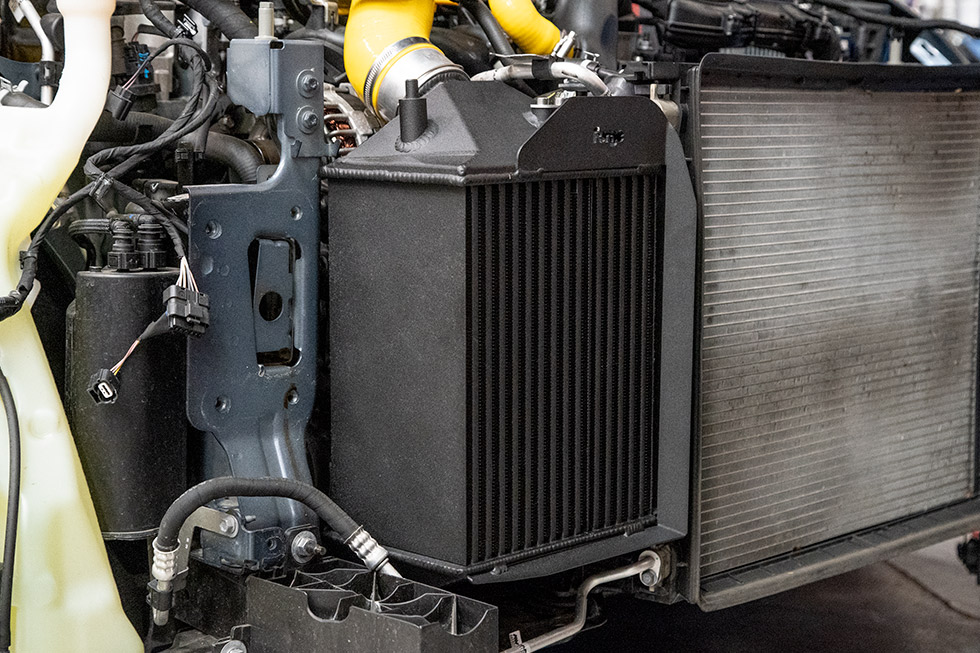

FMINT17 is our intercooler upgrade for the Renault Megane Mk4 R.S. We had received reports of this vehicle producing high IAT’s especially in hotter climates when driven hard. Our objective as always was to improve and overcome these issues as well as manufacture a product to the highest standard and quality. This however was not going to be a quick or easy process as with the Megane IV, R.S, Renault had decided to utilize a setup which does not lend itself well to improve its cooling package without a costly overhaul. Renault even went to the extent of using members of it’s F1 team to help with the design of this vehicle so the challenge to improve it cost effectively has been difficult, but with FMINT17, we have achieved this goal.

Using our highly skilled CAD team and fabrication department we went to work designing an intercooler which would occupy the original space without the need to modify the vehicle, while at the same time design a product with a greater capacity core for the optimum performance.

The end tanks have been a key part of the design of this intercooler, and we have opted for our classic and proven sheet metal construction which is folded in a way to produce a shallow and fast flowing design with negligible back pressure. It is also lightweight as this was another key element in our design brief, to manufacture a high performing intercooler as light as we can; this element also has a significant impact on our choice of intercooler core.

Once we had produced an end tank design, we specified several different intercooler core constructions before we started our vigorous dyno testing. Our research and compiled data pointed to the use of a tube and fin core construction, this UK manufactured component really worked well and again was the best option to keep weight to a minimum. The stepped core design is 41% larger in capacity over the OE intercooler and the final product achieved gains of 8bhp with an increase of 12NM of torque between 1900 RPM and 2500 RPM along with 20NM between 5500 RPM and 6000 RPM.This makes the Megane feel and pull stronger at the top of the rev band and when combined with a vehicle equipped with upgraded ECU software like our development vehicle the whole package transforms the 1.8T power plant into the motor this Megane R.S deserves.

FMINT17 is finished in our anti-corrosion powder coating which not only helps preserve this intercooler from harsh environments it also aids its thermal properties. As with all Forge Motorsport fabricated products this intercooler has the legendary Forge Lifetime warranty.

Why do we test different cores?

Here at Forge Motorsport, when developing an intercooler, we will test several different cores for each application. For example, a bar and plate style core, a tube and fin style core along with different fin pitches and heights e.g. 22 fins per inch or 17 fins per inch, as well as changing the internal fin pitches/shapes and density within the tube enabling to fine tune the amount of pressure drop the intercooler produces.

Pressure drop is not always a bad thing, as our testing and research has proven on various projects. This is because the pressurized air velocity is being stalled by the pressure drop within the cooler thus allowing more time to cool the air within the cooler itself, as air passes through the non-pressurized face of the core that is open to the atmosphere. Too much pressure drop can of course have a problem on the higher performance engines as the intercooler reaches its maximum efficiency the turbo has to work a lot harder to force the air through the core. This in turn creates higher inlet air temps (IAT’s) due to the turbo creating more heat as it is over stressed and worked harder.

Having no pressure drop can also prove to be inefficient as the cooler will not lower the charge temperature again resulting in higher inlet air temperatures.

Dyno Results

Testing was completed on Litchfield’s Maha dyno, manufactured by the same people who currently supply BMW M sport and Mercedes Benz for all their engine calibration and dyno testing. We also took the opportunity to use Performance Remap Gloucester dyno to compare results and ensure the most accurate data.

The stepped core design is 41% larger in capacity over the OE intercooler and the final product achieved gains of 8bhp with an increase of 12NM of torque between 1900 RPM and 2500 RPM along with 20NM between 5500 RPM and 6000 RPM.

Complimentary Products

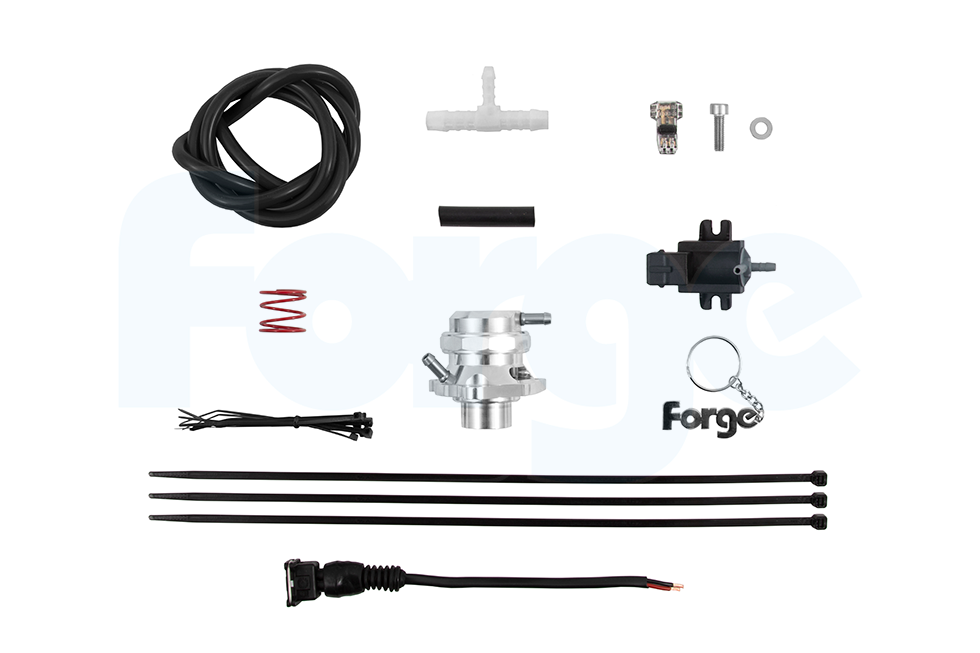

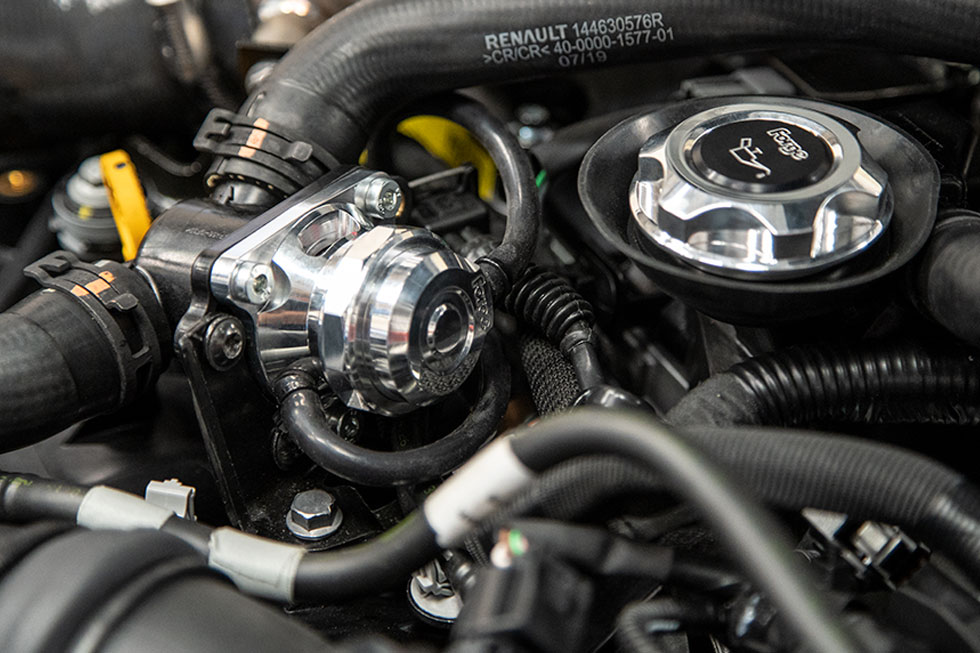

This blow off, or dump valve, is for the Renault and Nissan Turbo engines that have the electronically controlled bypass valve (OEM Part no. 144839204R). It is recommended for any vehicle where the boost pressure has been increased by an ECU software upgrade and for unmodified vehicles operating in warmer climates, as a solution to the many failures that have occurred.

With the success of the existing range of Forge Motorsport product for the Renault Megane R.S 280/300, we have decided to further expand our tuning parts range for this vehicle. We are excited to offer the FMTIA4 turbo inlet adaptor. Designed and developed by our highly skilled team on the SolidWorks CAD system, the all billet turbo adaptor and high flow silicone inlet pipe is proven to benefit your engines performance.

The Renault Megane RS 280/300 intake is the result of widespread design trials through dyno testing and flow analysis. It was developed to achieve three main objectives: Maintain low inlet temperatures in comparison to other aftermarket induction kits; Improved air flow; look aesthetically pleasing and enhances the look of your engine bay

Forge Motorsport - Innovatie en Kwaliteit

![]()

Forge Motorsport werd opgericht in 1996 met de eenvoudige idealen van innovatie, slim ontwerp en fabricage van de hoogste kwaliteit. Het evolueerde vanuit het oorspronkelijke Forge Engineering, dat in 1983 werd opgericht om innovaties en oplossingen te bieden aan verschillende industrieën.

Missie en Visie

Onze bedrijfsmissie stelt duidelijk onze toewijding en richting vast - 'Samenwerken aan het innoveren van automotive en technische oplossingen.' Deze missie stelt ons in staat om onze visie te realiseren van 'vertrouwen inboezemen en prestaties mogelijk maken in alles wat we doen.'

Wereldklasse Producten

Met de missie en visie die breed worden begrepen en erkend binnen het bedrijf, wordt het ontwerp- en fabricageproces aangedreven door een zeer bekwame en gepassioneerde team, dat gemotiveerd is om een reeks aftermarkt tuningproducten te produceren die van wereldklasse zijn.

Unieke Ervaring

Wanneer een forge intercooler bij ons koopt, koop je niet zomaar een onderdeel of product, je wordt lid van een unieke wereldwijde groep kritische consumenten die echt waarde, kwaliteit en service begrijpen, waardoor de Forge-eigendom een unieke ervaring wordt.

Video

Wereldwijde Erkenning

Onze geschiedenis en erfgoed stellen Forge Motorsport in staat om voorkeursleveranciers en technische partners te zijn die gehomologeerde onderdelen leveren aan BTCC & Mini Challenge, evenals de toonaangevende namen en raceteams in de wereld van de autosport, waaronder: F1, WRC, Rally X en Le Mans.

Gemoedsrust

Forge Motorsport zal je iets unieks leveren, iets wat geen enkele andere fabrikant kan bieden. Je investeert in gemoedsrust en de wetenschap dat ware zakelijke integriteit en zorg daadwerkelijk bestaan.

Beoordelingen

Nog geen beoordelingen